Contact us

Find the products your practice needs to succeed.

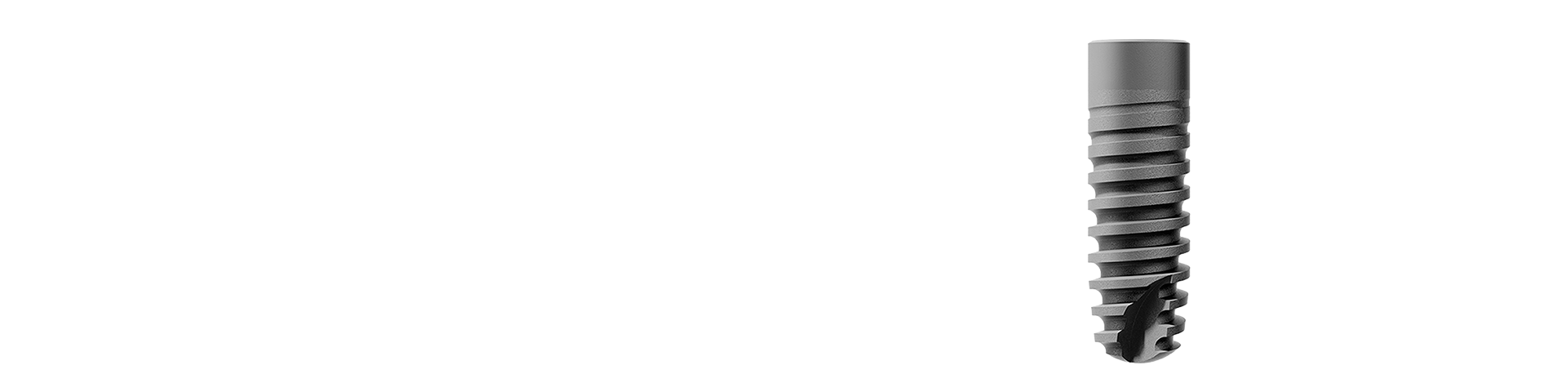

Bring innovation to your practice with Ankylos.

Excellence without exception

Ankylos is for people who demand excellent results. With more than 30 years’ proven clinical experience, this innovative, worldclass implant technology is thoroughly established and deliver what all patients want- front-row smiles.

Our Ankylos TissueCare Concept is scientifically and clinically proven to do exactly what the name implies. The Ankylos C|X implant system is for single-stage or two-stage surgical procedures.

Benefits

Why choose Ankylos?

Increased tissue stability

Subcrestal implant placement combined with horizontal offset and concave abutment design creates a three-dimensional space ideal for growing and maintaining healthy tissue and bone

Lasting tissue stability

Over 55,000 implants and more than 20,000 patients have been evaluated during up to 20 years period and the implant survival rate is >97% after 5+ years, as well as proven stable bone levels after 5 to 12 years of follow-up

Crestal bone preservation

Thread design matches bone function, simplifies insertion and helps maintain the crestal bone. Enables primary stability and immediate loading

Early osseointegration and rapid bone formation

The grit-blasted and high-temperature-etched surface ensures superior bone-to-implant contact, speeding up the bone formation

Simplified treatment process

Tapered TissueCare connection eliminates micromovements while promoting friction lock, reducing risks of bacterial growth and inflammation

Implanting TissueCare

The Ankylos TissueCare concept is scientifically and clinically proven and provides lasting tissue stability and excellent esthetic results.

One-fits-all: TissueCare connection

All abutments, regardless of size, share the same tapered connection, which simplifies the treatment process. A steep connection taper promotes friction lock and eliminates micromovement, thereby providing nonindexed prosthetics with an indexed option.

Progressive thread

The progressive thread design means the functional load is transferred to the apical part of the implant, creating primary stability and enabling immediate loading.

SoftTissue Chamber

The TissueCare connection and microrough implant shoulder make subcrestal placement possible. Together with a horizontal offset and concave abutment design, they create a three dimensional chamber for soft tissue and bone, which in turn increases tissue stability.

FriadentPlus surface

The microstructure of the grit-blasted and high temperature-etched Friadent plus implant surface provides superior bone-to-implant contact, promotes early osseointegration and results in rapid bone formation.

Tissue Stability over time

The true value of an implant system reveals itself with time. For over 30 years, the Ankylos implant system has stood for reliable, lasting esthetics. Numerous publications and long term clinical experience clearly demonstrate that Ankylos maintains hard and soft tissue stability, resulting in natural looking esthetics that last.

A full implant range

With a wide variety of lengths (6.6-17 mm) and diameters (3.5-7.0 mm), there is an Ankylos implant for every case.

Full prosthetic flexibility

There are Ankylos prosthetics for all clinical indications and your preferred approach.

Micro-rough implant shoulder

The patented microstructure implant shoulder promotes bone formation up to the abutment. This supports the overlying soft tissue and creates the perfect conditions for stability and lasting tissue health.

Horizontal offset (platform switching)

Thanks to the geometry of the Ankylos TissueCare connection, the transition between implant and abutment shifts to a more central position. This horizontal offset creates the perfect conditions for hard and soft tissue stability at the implant shoulder. And when combined with other benefits like no micromovement and no bacterial growth, it also provides lasting tissue maintenance.

Downloads

Further downloads are provided within our Download Center.

Please note: All products may not be regulatory cleared/released/licensed in all markets. Contact the local Dentsply Sirona sales office for current product assortment and availability.